EUTECT E-ssembly

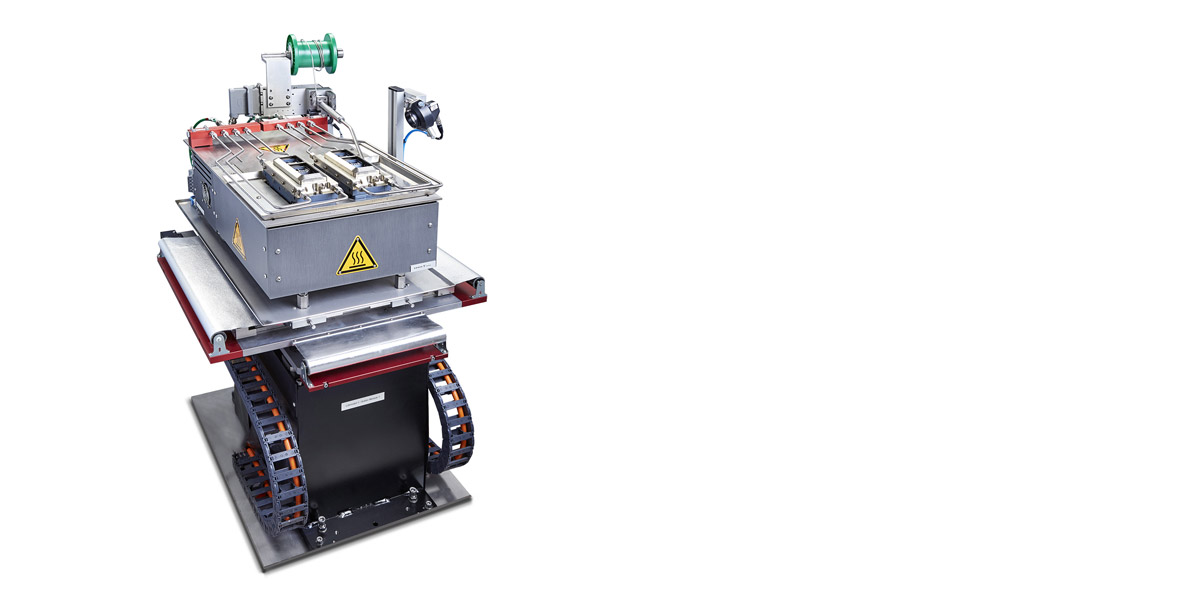

XPlanar automation for today’s and tomorrow’s inline manufacturing

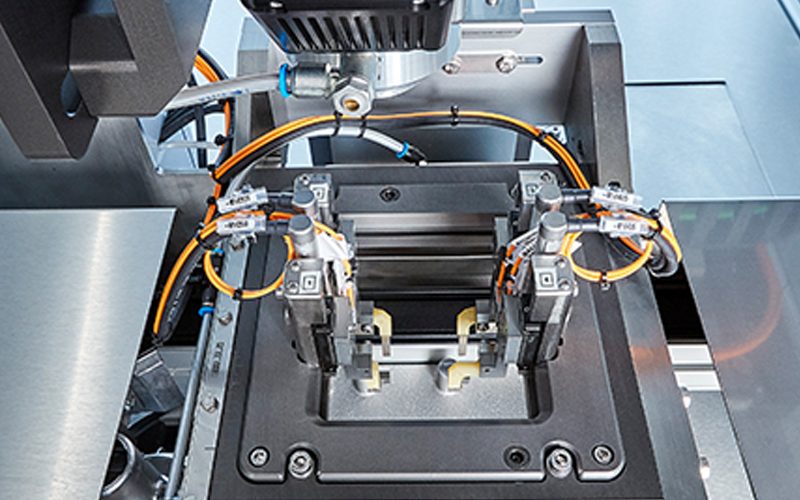

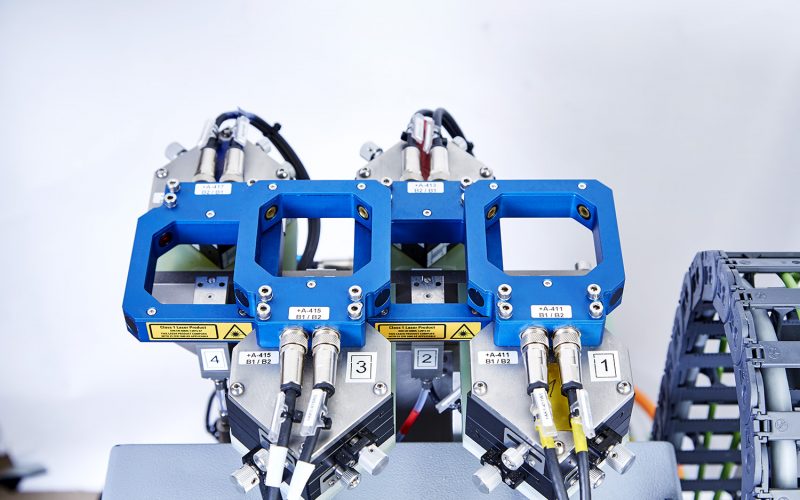

The floating product transport by means of the XPlanar from Beckhoff, which we have implemented in our E-ssembly concept, creates completely new possibilities for handling products inside and outside the machines as well as between the individual process steps. This means that we can look at inline production in a completely new way, and this has opened up possibilities that cannot be implemented with conventional belt transport systems.

Interactive, digital modular kit, incl. watch list function

For more than 15 years, our modular kit has presented the entire range of modules from which we configure the machine solutions for your selective soldering processes. We have now transferred this modular kit into the digital age to offer easier operation, a better overview, more information, interactivity and a strong link to the other product information.

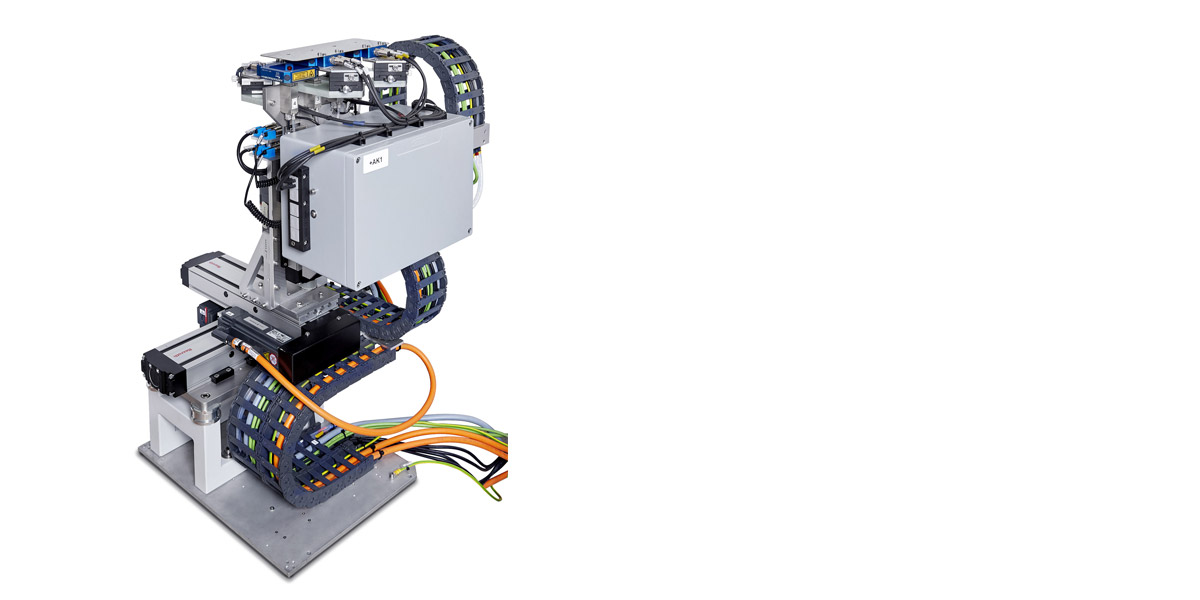

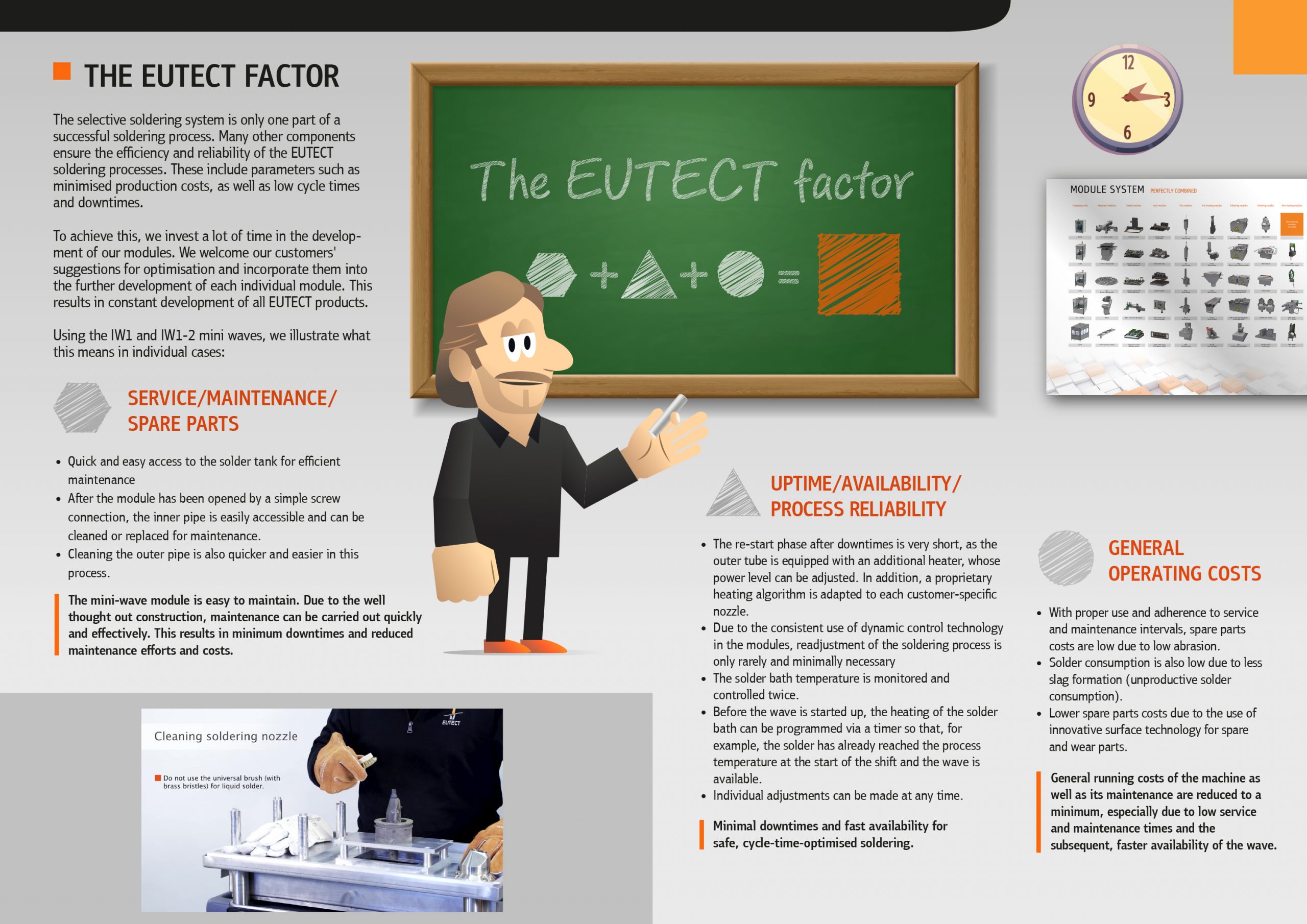

Many pieces of the puzzle make the EUTECT soldering processes efficient and reliable.

This includes parameters such as minimized production costs, as well as low cycle times and downtimes.

To achieve this, we invest a lot of time in the development of our modules. We take our customers’ suggestions for optimization and incorporate them into the further development of each individual module. This results in constant further development of all EUTECT products.

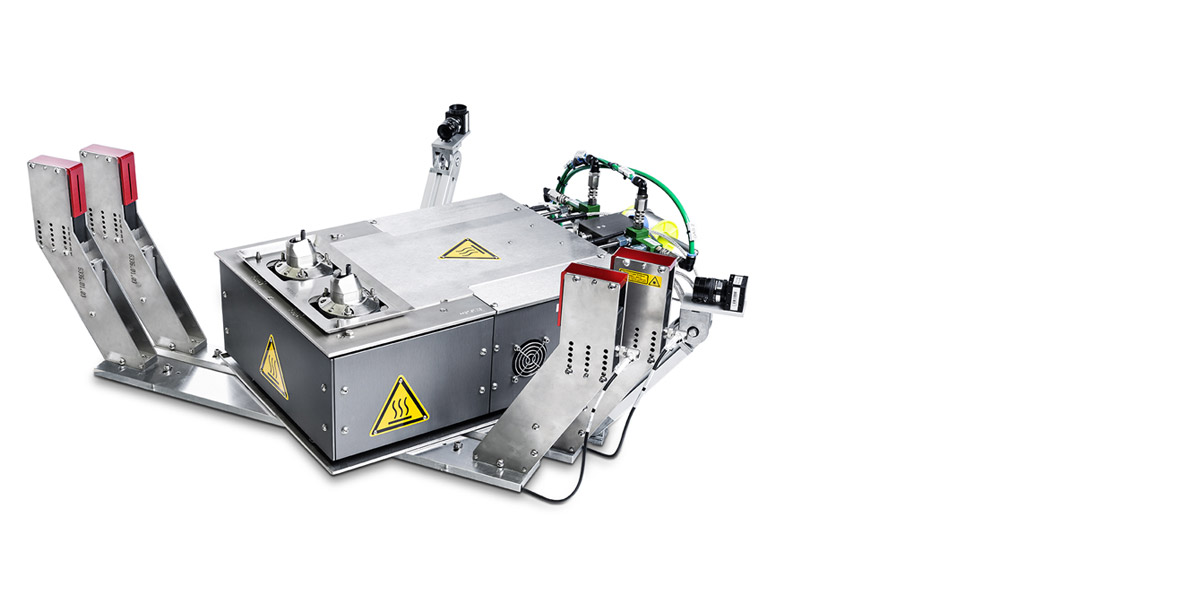

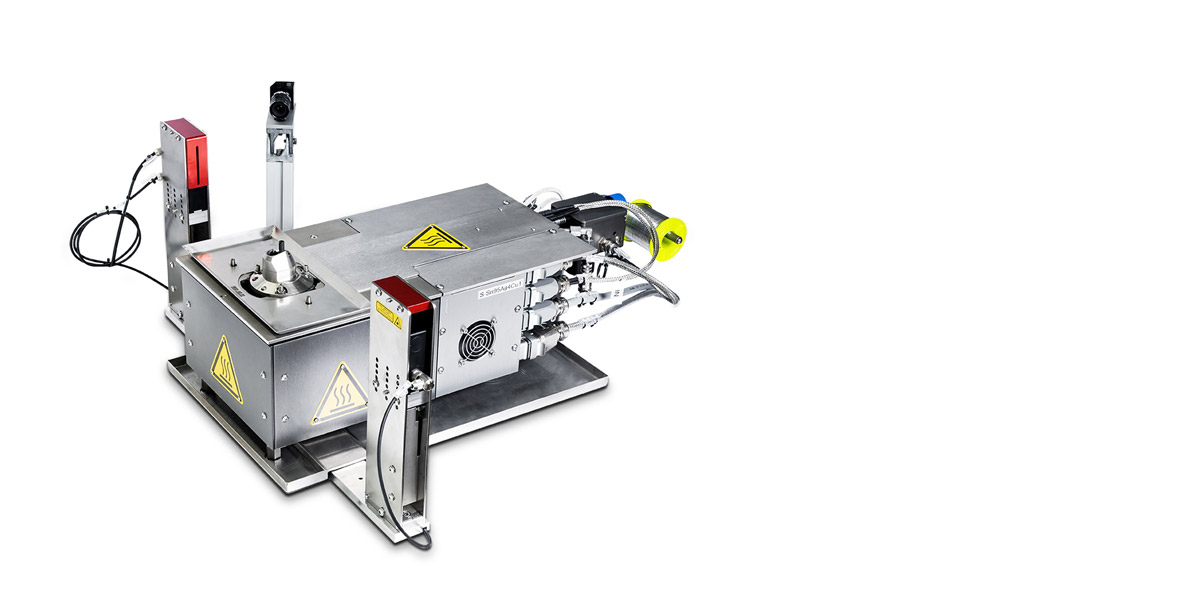

Using the IW1 and IW1-2 mini-waves, we illustrate what this means in individual cases.

New EUTECT product brochure

We have taken the communication of our processes & modules to a new level.

Together with our partner Butter and Salt tech marketing GmbH, we have developed an interactive brochure that combines static and interactive information.

In this, for example, videos about our processes can be played directly. In this way we manage to offer information from different media compactly to the brochure user.

In addition, direct links are built in to get information about further solutions online.

EUTECT – Machines Portfolio

Technical complexity does not always make a product unique

Uniqueness means finding easy and efficient solutions to overcome the challenges in soldering automation.

The basis for this is listening, asking questions and a common understanding.

Matthias Fehrenbach, Managing Director